More About Grit Blasting

Portable Sandblaster for Beginners

Table of ContentsGetting The Sand Blasting Sand To WorkThe Main Principles Of Black Diamond Blasting Sand An Unbiased View of Abrasive BlastingDustless Blasting Near Me Fundamentals ExplainedOur Sandblasting PDFsMobile Sandblasting Near Me Can Be Fun For Everyone

Damp unpleasant blasting usages water as the fluid moving the abrasives. The water supports the effect on the surface, reducing the removal of sound material. One of the original pioneers of the damp unpleasant procedure was Norman Ashworth that located the advantages of making use of a damp procedure as a solid choice to completely dry blasting.

Lowered impregnation of blowing up material right into the surface area, dirt reduction and the elimination of static stick can lead to a spick-and-span surface - pressure washer sandblaster. Wet blasting of mild steel will result in prompt or 'flash' deterioration of the blasted steel substratum because of the existence of water. The lack of surface area recontamination additionally permits the use of single devices for numerous blasting operationse.

The Greatest Guide To Grit Blasting

Vapor blowing up [edit] A variation of wet blowing up is vapor blasting (or vapour blasting; U.K.). In this procedure pressurized air is included in the water in the nozzle creating a broadband mist, called "vapor". This procedure is even milder than wet blasting, enabling breeding surfaces to be cleaned while preserving their ability to mate.

Mixing fragments with water considerably minimizes dust. Grain blasting is the procedure of getting rid of surface deposits by using great glass beads at a high pressure without damaging the surface area.

In getting rid of paint for car body job, grain blasting is liked over sand blasting, as sand blasting often tends to develop a greater surface profile than bead blasting. Bead blasting is typically used in creating a consistent surface coating on machined parts.

About Portable Sandblaster

The first blast wheel was patented by Wheelabrator in 1932. In China, the first blast wheel was developed around the 1950s, Qinggong Equipment is among the earliest suppliers of blast wheel. Hydro-blasting [edit] Hydro blasting is not a form of unpleasant blasting as no rough media is made use of. Hydro-blasting, generally called water blasting, is frequently utilized because it typically requires only one driver.

This technique is ideal for cleansing interior and external surfaces since the driver is usually able to send out the stream of water into areas that are hard to get to utilizing other methods. One more benefit of hydro-blasting is the capability to regain as well as reuse the water, decreasing waste and mitigating ecological influence.

Higher pressures are often called for. One of the most typical micro-abrasive blasting systems are commercial bench-mounted units including a power supply and mixer, exhaust hood, nozzle, and also gas supply. The nozzle can be hand-held or fixture mounted for automated operation. Either the nozzle or component can be relocated automated procedure.

Sandblaster For Sale Fundamentals Explained

Automated blasting is frequently just a step in a bigger automated procedure, usually involving other surface treatments such as prep work and also finishing applications.

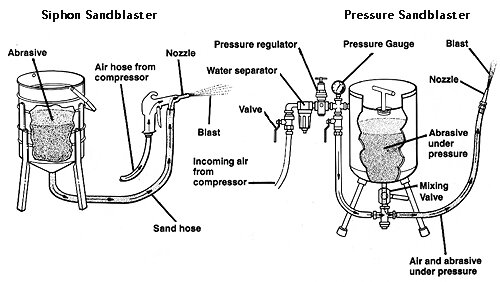

The air compressor provides a huge quantity of high stress air to a single or why not check here multiple "blast pots". Blast pots are pressurized, tank-like containers, full of unpleasant material, used to allow an adjustable amount of blasting grit into the primary blowing up line. The number of blast pots is determined by the quantity of air the compressor can give.

Wet blowing up is commonly utilized in applications where the very little dirt generation is wanted. Portable applications may or may not reuse the rough.

Top Guidelines Of Dustless Blasting Near Me

There are 3 systems generally made use of in a blast cabinet. 2, siphon and also pressure, are dry and one is damp: A siphon blast system (suction blast system) makes use of the pressed air to create vacuum cleaner in a chamber (known as the get more blast gun). The negative stress pulls abrasive into the blast gun where the pressed air routes the abrasive via a blast nozzle.

Silicon carbide and boron carbide nozzles are much more put on resistant as well as are frequently made use of with more challenging abrasives such as aluminium oxide. Inexpensive rough blasting systems and also smaller closets use ceramic nozzles.

What Does Sandblasting Near Me Mean?

The vessel is pressurized to the same stress as the blast pipe attached to all-time low of the stress vessel. The rough is metered into the blast tube and communicated by the pressed gas via the blast nozzle. Wet blast cupboards use a system that infuses the abrasive/liquid slurry right into a pressed gas stream.